Keeping Your Jeep Running Smoothly: A Guide to Changing your Differential Oil

Jeep Wrangler ‘Maintenance Schedule’ Series

Changing the differential oil is an essential maintenance task for any Jeep Wrangler owner. The oil lubricates and cools the gears, and over time, it can break down and lose its effectiveness. Changing your differential oil is a straightforward process that can be done in your driveway with the right tools and some patience. In this installment of the Jeep Wrangler ‘Maintenance Schedule’ Series, we’ll take a look at the steps involved.

Now, let’s get started with the process of changing the differential oil:

Step 1: Gather Materials and Tools

To change the differential oil, you will need the following materials and tools:

- Differential oil

- Drain pan

- Socket wrench set

- Torque wrench

- Funnel

- Shop towel

- A new gasket or RTV silicone

- Scraper or wire brush (optional)

- spray paint (optional)

- Break Cleaner

Step 2: Prepare the Vehicle

Park the Jeep on a level surface and engage the parking brake. Chock the wheels to prevent the vehicle from rolling. Then, crawl under the Jeep and locate the differential cover.

Step 3: Remove the Differential Cover

Using your socket wrench set, remove the bolts that secure the differential cover to the housing. Start with the bottom bolts and work your way up to the top bolts. leaving the top bolt loose but in-place, gently pry the cover off the housing. Be careful not to damage the gasket surface.

Step 4: Drain the Oil

Using the drain pan, collect the old oil as it drains out of the differential housing. Once the oil has drained out, use the shop towel to wipe the inside of the housing and the cover clean. Using brake cleaner to clean the gears is a simple and effective way to remove dirt, debris, and old oil from the gears before refilling with fresh oil. Spray brake cleaner directly onto the gears and other internal parts of the differential housing. Be sure to apply the cleaner liberally to ensure that all surfaces are thoroughly cleaned.

Step 5: Check for Wear

While the differential cover is off, inspect the gears and bearings for any signs of wear or damage. Look for chips, cracks, or abnormal wear patterns on the gears and check for excessive play in the bearings.

When checking for wear on your Jeep Wrangler’s differential, there are several key areas to inspect. These include:

- Ring and Pinion: Inspect the ring and pinion gear teeth for wear, cracks, or damage. Look for signs of pitting, scoring, or discoloration on the gear teeth, as these can indicate excessive wear or damage.

- Bearings: Check the differential bearings for wear or damage. Look for signs of pitting, scoring, or rust on the bearing surfaces. A worn or damaged bearing can cause excessive noise, vibration, or even failure.

- Spider Gears: The spider gears, which transfer power between the left and right wheels, should be inspected for wear or damage. Look for signs of pitting, scoring, or wear on the gear teeth. Excessive wear or damage can cause the gears to slip, reducing traction and potentially causing further damage.

- Axle Shafts: The axle shafts should be inspected for wear or damage. Look for signs of pitting, scoring, or bending on the shafts. Worn or damaged axle shafts can cause excessive noise, vibration, or even failure of the differential.

If any of these areas show signs of wear or damage, it is important to address the issue promptly to prevent further damage or failure of the differential. Depending on the extent of the wear or damage, the differential may need to be repaired or replaced entirely. It’s always a good idea to consult a qualified mechanic or service technician if you’re unsure about the condition of your Jeep Wrangler’s differential.

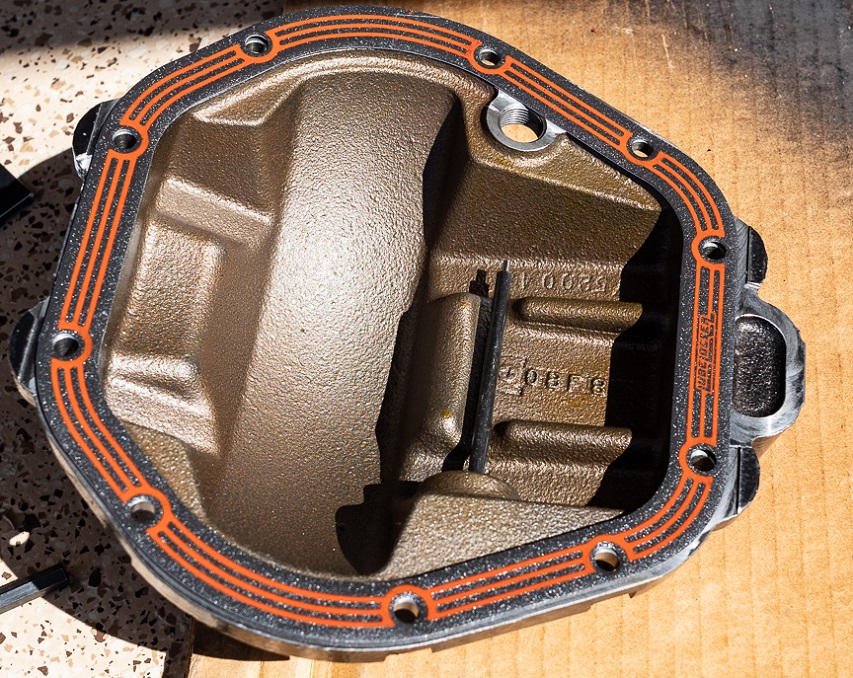

Step 6: Clean & Paint the Differential Cover (Optional)

Now is a good time to clean and paint the differential cover if desired. Use a degreaser and a wire brush to remove any dirt or rust from the cover. Then, apply a rust-inhibiting paint or primer followed by a topcoat of your preferred color. Common colors for Jeep Wrangler differential covers include black, silver, and red.

Step 7: Replace or Reseal the Gasket

When it comes to resealing the differential cover on your Jeep Wrangler, there are two main options: using a gasket or using RTV silicone.

Gaskets are made of a variety of materials, including cork, rubber, and paper, and provide a reliable seal between the differential cover and housing. They are easy to install and can be reused several times if they are not damaged during removal.

RTV silicone is a liquid sealant that is applied directly to the differential cover or housing. It provides a strong and durable seal and is ideal for surfaces that are irregular or have small imperfections. However, it can be messy to work with and requires careful application to avoid leaks.

Ultimately, the choice between a gasket and RTV silicone comes down to personal preference and the condition of the differential cover and housing. If the surfaces are smooth and in good condition, a gasket may be sufficient. If there are small imperfections or irregularities, RTV silicone may provide a better seal.

Remove any old gasket material from the cover and housing using a scraper or wire brush. Then, install the new gasket or RTV silicone onto the cover. If using a gasket, make sure the gasket is positioned correctly. If using RTV, apply a nice even bead to the cover, circling each bolt hole.

Step 8: Reinstall the Differential Cover

Carefully align the differential cover with the housing and install the bolts. Tighten the bolts in a crisscross pattern, gradually increasing the torque to the manufacturer’s specifications. If using RTV, ensure the bead isn’t smeared sideways while reinstalling the cover.

Step 9: Add Limited-Slip Additive (if required)

If your Jeep Wrangler has a limited-slip differential, add the recommended amount of limited-slip additive to the new differential oil. Consult your owner’s manual or a mechanic to determine the correct amount. While Limited-slip differentials are not standard on all Jeep Wrangler models, they are available as an option on certain trims, most notably many Sahara and Rubicon models.

Step 10: Refill the Differential

Using the funnel, pour the new oil into the housing through the fill hole until it reaches the level specified in the owner’s manual. Install the fill plug and torque it to the manufacturer’s specifications.

In conclusion, changing the differential oil in your Jeep Wrangler is a simple yet critical maintenance task that can extend the life of your vehicle’s differential. It’s important to choose the right gasket and follow the manufacturer’s torque specifications when reinstalling the cover. Additionally, taking the time to clean and paint the differential cover can improve its appearance and protect it from rust and corrosion. By following these steps, you can ensure that your Jeep Wrangler’s differential is properly lubricated and functioning optimally for years to come.

1 thought on “Keeping Your Jeep Running Smoothly: A Guide to Changing your Differential Oil”

Comments are closed.