Off-Road Risks: 8 Common Jeep TJ Parts That Are Prone to Breakage on the Trail

Jeep Wrangler TJ is an iconic off-road vehicle that is loved by many for its ruggedness, durability, and off-road capabilities. However, when you start off-roading your Jeep TJ, you need to be aware of the common parts that may break or wear out faster than usual due to the added stress and impact of off-roading. In this article, we will discuss the most common parts that may break when you start off-roading your Jeep TJ, including control arm mounts and the radiator, and provide tips on how to prevent or fix them.

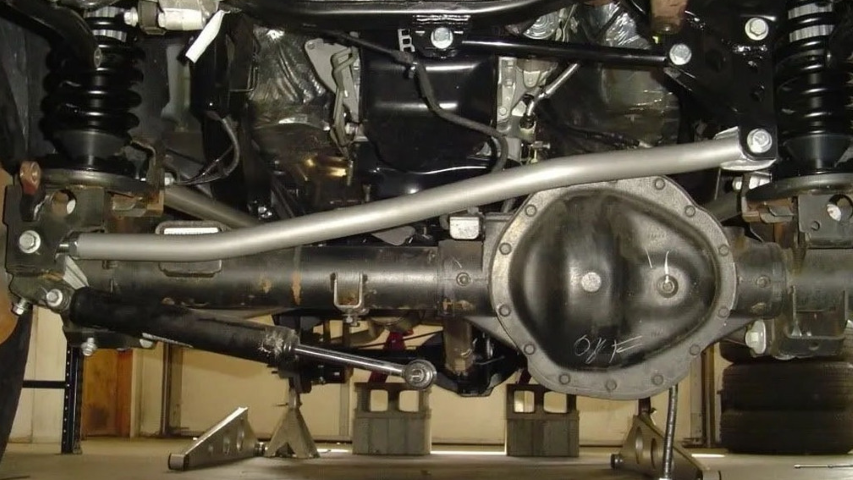

Control Arm Mounts

Control arm mounts are the connection points between the control arms and the frame of your Jeep TJ. One of the main reasons for these to daily on the trail is the extreme stress that is placed on the mounts when driving over rough terrain. The constant jolting and impact can cause the mounts to become weakened or damaged, which in turn can cause the control arms to become loose or even detach from the vehicle. This is especially true when the Jeep is driven aggressively or when the driver is attempting to navigate difficult obstacles.

Another factor that can contribute to control arm mount failure is the use of larger or more aggressive tires. When a Jeep is modified with larger tires, the increased weight and rolling resistance can put additional stress on the control arm mounts. Additionally, the increased traction provided by the tires can put more torque on the control arms, which can cause them to twist or flex, further compromising the integrity of the mounts. To avoid these issues, it is important for Jeep owners to regularly inspect their control arm mounts and ensure that they are properly reinforced and secured before hitting the trails.

Control Arms

Control arms are the linkages that connect the axle to the frame of your Jeep TJ. They help to absorb shock and maintain the stability of your vehicle. These control arms are often one of the components that are most prone to failure. This is because control arms are responsible for connecting the axle to the frame of the vehicle, and when driven off-road, the increased stress and vibrations can cause the control arms to weaken and eventually fail. The repeated jolts and impacts from driving over rocks, logs, and other obstacles can cause the control arms to bend, crack, or even break, resulting in a dangerous situation for the driver and passengers.

In addition, many off-road enthusiasts like to modify their Jeeps by adding larger tires or lifts, which can put even more stress on the control arms. Larger tires can add more weight to the vehicle, increasing the load on the control arms and causing them to wear out faster. Lifts can also affect the suspension geometry, which can cause the control arms to become misaligned and fail prematurely. Regular inspection and maintenance of control arms is critical to ensuring that they are functioning properly and do not put the driver and passengers at risk while off-roading.

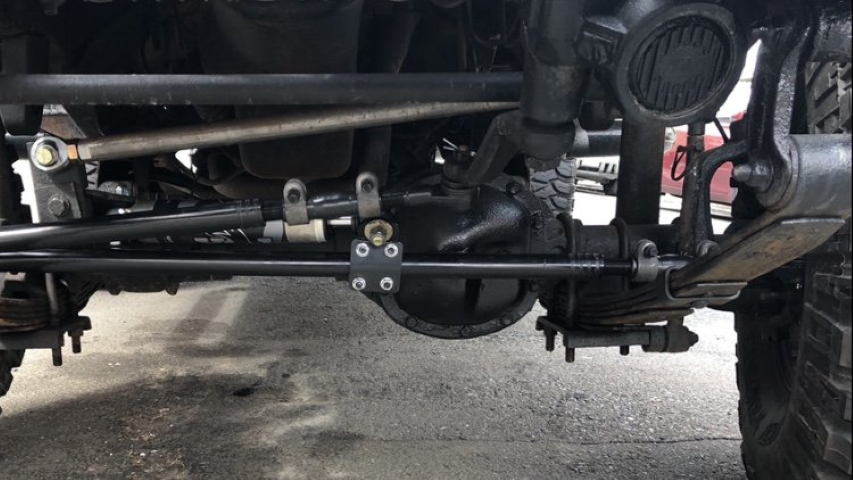

Track Bars

Track bars are responsible for keeping the axle centered under the vehicle and providing stability during turns and maneuvers. When a Jeep is taken off-road, the increased stress and vibration from driving over rough terrain can cause the track bars to weaken and eventually fail. This is especially true when the driver is navigating difficult obstacles, such as rocks or steep inclines, which can cause the track bars to twist or flex beyond their limits.

Another factor that can contribute to track bar failure is modifications to the suspension system. Many off-road enthusiasts like to add lift kits or larger tires to their Jeeps, which can affect the suspension geometry and cause the track bars to become misaligned. When the track bars are not properly aligned, they can experience uneven stress, which can cause them to bend or break. Regular inspection and maintenance of track bars is essential to ensure that they are functioning properly and are not putting the driver and passengers at risk while off-roading.

Radiator

Radiators play a crucial role in the cooling system of a Jeep, and when the vehicle is taken off-road, the increased stress and vibration can cause them to fail. When driving over rough terrain, the constant jolts and impacts can cause the radiator to become weakened or damaged, resulting in leaks or cracks. This is especially true when the Jeep is driven aggressively or when the driver is attempting to navigate difficult obstacles. Additionally, off-road driving often involves driving through mud, sand, and water, which can clog the radiator fins and reduce the airflow, causing the engine to overheat.

Furthermore, many off-road enthusiasts modify their Jeeps with larger tires, lift kits, and other aftermarket accessories that can put additional stress on the cooling system. Larger tires can increase the weight of the vehicle, making it harder for the engine to operate efficiently and causing it to generate more heat. Lift kits can also affect the position of the radiator and the airflow, causing the engine to run hotter than it should.

Unsurprisingly, since even the newest TJs are 15+ years old, a common cause for radiator failure is corrosion or rust. Over time, the metal parts of the radiator can corrode and deteriorate, especially if the Jeep is driven in areas with high humidity or salt exposure. Corrosion can lead to leaks or cracks in the radiator, which can cause the engine to overheat and potentially cause serious damage.

Similarly, the plastic components of the radiator, such as overflow tanks, can become brittle and crack due to age and exposure to heat. This can also lead to leaks and a loss of coolant, which can cause the engine to overheat and potentially result in engine damage.

It is important for Jeep owners to regularly inspect their radiators and cooling systems and ensure that they are functioning properly before heading off-road. Maintaining proper coolant levels, cleaning the radiator fins, and replacing damaged or worn components can help prevent radiator failure and keep the engine running smoothly while off-roading.

Axles

Axles are responsible for transferring power from the engine to the wheels, and when a Jeep is taken off-road, the increased stress and vibration can cause the axles to weaken and eventually fail. The repeated jolts and impacts from driving over rocks, logs, and other obstacles can cause the axles to bend, twist or even break, resulting in a dangerous situation for the driver and passengers.

Like most suspension and steering components, modifying Jeeps by adding larger tires or lifts can put even more stress on the axles. Larger tires can increase the load on the axles, making them work harder to transfer power to the wheels. Lifts can also affect the suspension geometry and cause the axles to become misaligned. Misaligned axles can cause the tires to wear unevenly and put additional stress on the axle components. Regular inspection and maintenance of axles are critical to ensure that they are functioning properly and do not put the driver and passengers at risk while off-roading.

Tie Rods

Tie rods are the linkages that connect the steering gear to the wheels. They help to maintain the alignment of your Jeep TJ’s front wheels. When off-roading, tie rods are put under significant stress and can wear out or break. The most common issue is the tie rod ends wearing out or becoming damaged. When this happens, you may experience steering wheel play, uneven tire wear, or a loss of control.

Tires

Tires are another critical part of your Jeep TJ, especially when off-roading. The tires provide the necessary traction, grip, and stability to tackle rough terrain and maintain control. However, when off-roading, the tires are more likely to wear out or get damaged due to sharp rocks or other obstacles. The most common tire-related issues when off-roading are punctures, sidewall cuts, and tread wear. To prevent or fix this issue, you should invest in high-quality off-road tires that are designed for rugged terrain and can withstand punctures and cuts.

While Jeep Wranglers are incredibly capable off-road vehicles, they are not without their vulnerabilities. The most common parts that can fail on a Jeep Wrangler during off-road use include the suspension system, drive train components, tires, and electrical systems. Regular maintenance and inspection can help identify potential issues before they become major problems, and upgrades or replacements of these components with more durable or high-performance options can help improve a Wrangler’s off-road capabilities and reliability. With proper care and attention, Jeep Wrangler owners can continue to enjoy the thrill of off-road adventures for many years to come.